Predictive Modeling and Non-linear Optimization Techniques for Composite Materials Design

DOI:

https://doi.org/10.52547/jcc.4.3.6Keywords:

Composite, Design, Modelling, Optimization, Taguchi, SensitivityAbstract

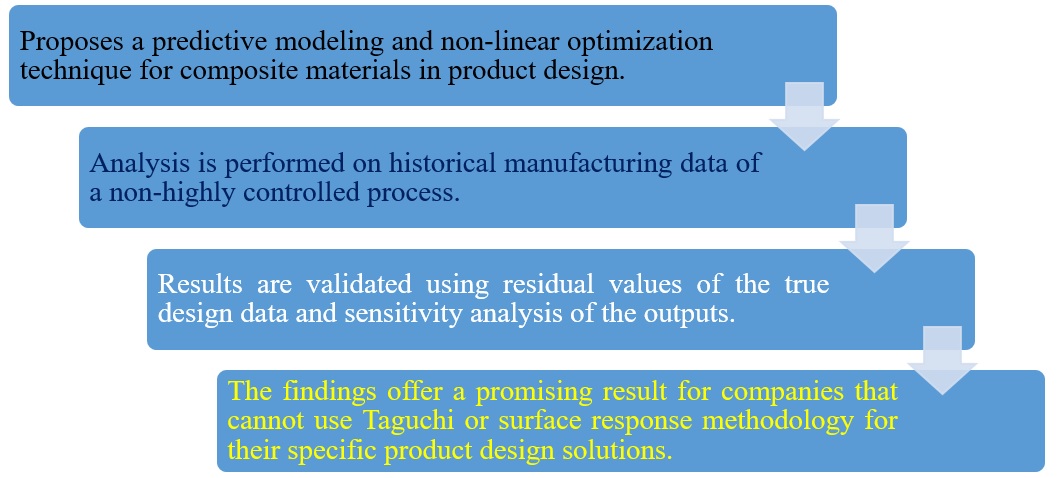

With the rise in the use of composite materials for product design, research has been performed in determining the optimal way to produce materials for given desired outputs. As of now response surface methodology and the Taguchi method are the front running methods for optimizing material production methods at the design level. This research investigates why these methods are not a one size fits all solution to optimizing composite materials production for material properties. It proposes utilizing predictive modeling and non-linear optimization techniques from historical manufacturing data of a non-highly controlled manufacturing process. The method is examined with the manufacturing and testing data of a local concrete product manufacturer. The models and optimization methods are validated with residual values to the true data and sensitivity analysis of the problem. The initial testing of the method offers promise to companies who have not found Taguchi or surface response methodology, applicable to their specific business solutions.

References

G. Liu, X. Zhang, X. Chen, Y. He, L. Cheng, M. Huo, J. Yin, F. Hao, S. Chen, P. Wang, S. Yi, L. Wan, Z. Mao, Z. Chen, X. Wang, Z. Cao, J. Lu, Additive manufacturing of structural materials, Materials Science and Engineering: R: Reports 145 (2021) 100596.

D.K. Rajak, D.D. Pagar, R. Kumar, C.I. Pruncu, Recent progress of reinforcement materials: a comprehensive overview of composite materials, Journal of Materials Research and Technology 8(6) (2019) 6354-6374.

S.L. Ogin, P. Brøndsted, J. Zangenberg, 1 - Composite materials: constituents, architecture, and generic damage, in: R. Talreja, J. Varna (Eds.), Modeling Damage, Fatigue and Failure of Composite Materials, Woodhead Publishing2016, pp. 3-23.

M.S. Phadke, Introduction to robust design (Taguchi method)—Isixsigma, 2019.

J.C. Nash, The (Dantzig) simplex method for linear programming, Computing in Science and Engineering 2(1) (2000) 29-31.

A. International, Standard test method for short-beam strength of polymer matrix composite materials and their laminates, ASTM International2016.

Taguchi Designs. Minitab Support: Minitab Support, (2019).

D. Astm, Standard test method for tensile properties of polymer matrix composite materials, ASTM International, West Conshohocken, PA (2017).

Astm, American Society for Testing and Materials. ASTM G99-17: standard test method for wear testing with a pin-on-disk apparatus, ASTM West Conshohocken.

D. Astm, ASTM D 256-10 standard test methods for determining the Izod pendulum impact resistance of plastics, American Society for Testing and Materials, West Conshohocken, PA (2018).

ASTM. Standard Guide for Identification of Fiber-Reinforced Polymer-Matrix Composite Materials, D8335- 20 ASTM International, West Conshohocken, PA, 2020.

Y. Inaguma, H. Sato, Y. Watanabe, Fabrication of Al-Based FGM Containing TiO2 Nano-Particles by a Centrifugal Mixed-Powder Method, Materials Science Forum 631-632 (2010) 441-447.

A. Patnaik, A.D. Bhatt, Mechanical and dry sliding wear characterization of epoxy–TiO2 particulate filled functionally graded composites materials using Taguchi design of experiment, Materials and Design 32(2) (2011) 615-627

Ö. Sava?, Application of Taguchi’s method to evaluate abrasive wear behavior of functionally graded aluminum based composite, Materials Today Communications 23 (2020) 100920.

A. Cuevas, Using the Taguchi Design and the Central Composite Design to Increase the Robustness of a Process from its Raw Material Variability, (2009).

L. Wang, Recommendations for Design Parameters for Central Composite Designs with Restricted Randomization, (2006).

J. Nash, The (Dantzig) simplex method for linear programming. Computing in Science and Engineering, 2000, 2(1), 29–31.

C.A.C. Coello Coello, G.T. Pulido, A micro-genetic algorithm for multiobjective optimization, Springer, pp. 126-140.

G. Rudolph, Convergence analysis of canonical genetic algorithms, IEEE Transactions on Neural Networks 5(1) (1994) 96-101.

J.C. Lagarias, J.A. Reeds, M.H. Wright, P.E. Wright, Convergence Properties of the Nelder--Mead Simplex Method in Low Dimensions, SIAM Journal on Optimization 9(1) (1998) 112-147.

R.Q. Sardinas, P. Reis, J.P. Davim, Multi-objective optimization of cutting parameters for drilling laminate composite materials by using genetic algorithms, Composites Science and Technology 66(15) (2006) 3083-3088.

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 The University of Georgia Publishing House (UGPH)

This work is licensed under a Creative Commons Attribution 4.0 International License.