Optimization of the parameters of ultrasonic aided drilling of Al/SiC composite by genetic algorithm

DOI:

https://doi.org/10.52547/jcc.4.3.2Keywords:

Ultrasonic aided machining, Optimization, Genetic algorithm, Surface smoothness, Experimental designAbstract

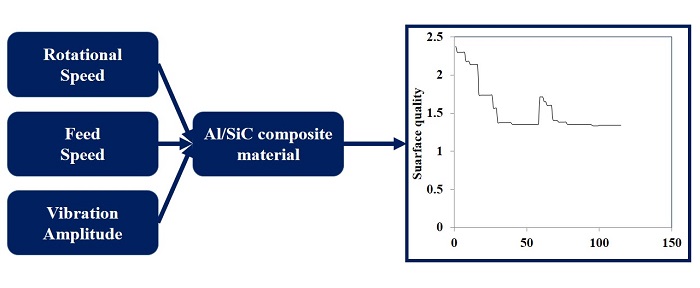

The surface quality of the industrial samples is one of the important factors in manufacturing industry, especially in drilling processes. It is well-known that ultrasonic vibrations can help to improve surface roughness and eliminate the pleat in drilled holes. The use of ultrasonic waves in the machining process also increases the dimensional accuracy of the produced pieces. In this study, the effect of few parameters including rotational speed, feed speed and amplitude of the vibration on the roughness of the drilled walls in the process of drilling with the aid of ultrasonic vibration was performed on Al/SiC composite material. Based on the experimental data, the fitness function was designed and modeled and using the genetic algorithm technique, optimal machining variables were obtained to improve the surface finish of the machined work piece. The results showed that by increasing the amplitude of the vibration and the rotational speed of the tool, a smoother surface can be achieved. The results obtained from the genetic algorithm as well as the experiments showed the ability of the genetic algorithm technique to optimize the machining process of the aluminum silicon carbide composite.

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 The University of Georgia Publishing House (UGPH)

This work is licensed under a Creative Commons Attribution 4.0 International License.