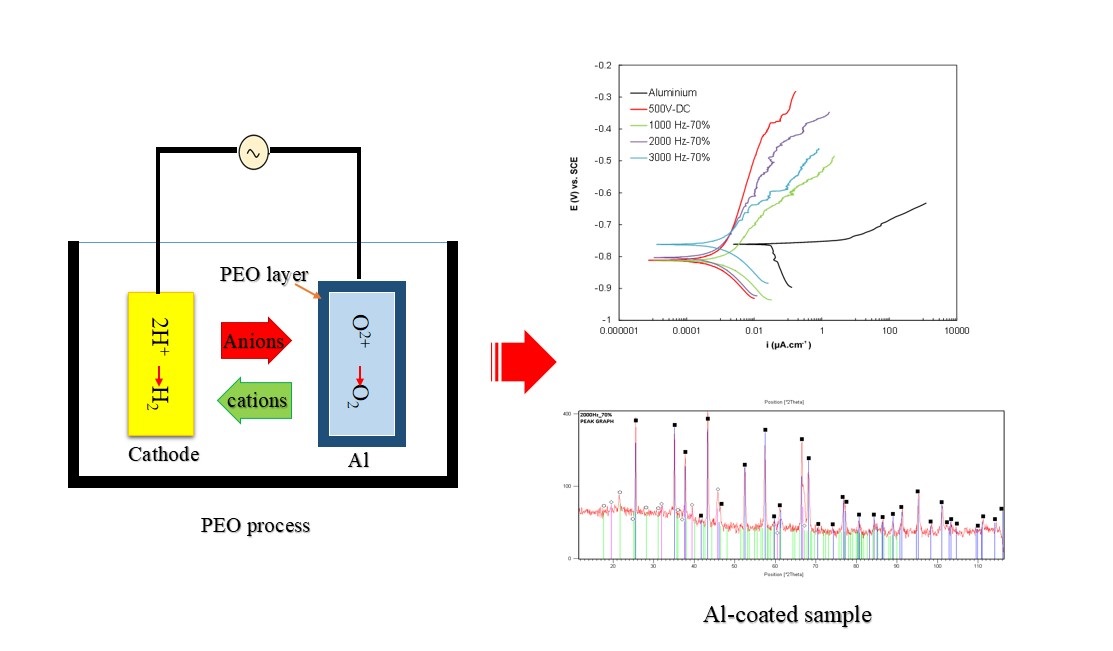

Corrosion behavior of aluminum oxide coatings created by electrolytic plasma method under different potential regimes

DOI:

https://doi.org/10.29252/jcc.2.3.4Keywords:

Plasma electrolytic oxidation, Aluminum oxide coatings, Potential regime, CorrosionAbstract

The electrolytic plasma coating is affected by various factors such as electrolyte conductivity, voltage, and current. However, there has not been much attention to the effect of the current regime. The main objective of the present study is to investigate the potential of Al2O3 coatings deposited by the electrolytic plasma method. Aluminum Series 2 was used in this study and the electrolyte was composed of sodium silicate, sodium tetraphosphate, sodium aluminate and potassium hydroxide. The results showed that, in general, according to the impedance diagrams, the corrosion resistance of the coated specimens greatly increases with the immersion time. Therefore, the unit of resistance increased on average to about 10 MHz after 72 hours. In the case of pulsed potential application regime, the corrosion behavior of the samples in the working cycle of 30% was better than that of 70%, which can be related to the thickness of the formed coatings and their porosity. This allows the coating to degrade the coating faster by increasing the thickness and decreasing the porosity of the aggressive chloride ion.

References

I. Tajzad, E. Ghasali, Production methods of CNT-reinforced Al matrix composites: a review, Journal of Composites and Compounds 2(1) (2020) 1-9.

K. Zhang, H.W. Jang, Q. Van Le, Production methods of ceramic-reinforced Al-Li matrix composites: A review, Journal of Composites and Compounds 2(3) (2020) 77-84.

F. Sharifianjazi, M. Moradi, A. Abouchenari, A.H. Pakseresht, A. Esmaeilkhanian, M. Shokouhimehr, M.S. Asl, Effects of Sr and Mg dopants on biological and mechanical properties of SiO2–CaO–P2O5 bioactive glass, Ceramics International (2020).

B. Ghorbanian, S.M.M. Khoie, Formation of vanadium carbide with the plasma electrolytic saturation method (PES) and comparison with Thermo Reactive diffusion method (TRD), Acta Metallurgica Slovaca 22(2) (2016) 111-119.

S. Nasibi, K. Alimohammadi, L. Bazli, S. Eskandarinezhad, A. Mohammadi, N. Sheysi, TZNT alloy for surgical implant applications: A systematic review, Journal of Composites and Compounds 2(3) (2020) 62-68.

B. Kasalica, M. Petkovic-Benazzouz, M. Sarvan, I. Belca, B. Maksimovic, B. Misailovic, Z. Popovic, Mechanisms of plasma electrolytic oxidation of aluminum at the multi-hour timescales, Surface and Coatings Technology (2020) 125681.

T. Kikuchi, T. Taniguchi, R.O. Suzuki, S. Natsui, Fabrication of a plasma electrolytic oxidation/anodic aluminum oxide multi-layer film via one-step anodizing aluminum in ammonium carbonate, Thin Solid Films 697 (2020) 137799.

W. Liu, C. Blawert, M.L. Zheludkevich, Y. Lin, M. Talha, Y. Shi, L. Chen, Effects of graphene nanosheets on the ceramic coatings formed on Ti6Al4V alloy drill pipe by plasma electrolytic oxidation, Journal of Alloys and Compounds 789 (2019) 996-1007.

L. Famiyeh, H. Xiaohu, Improving Corrosion Resistance and Mechanical Properties of Aluminum and its Alloys via Plasma Electrolytic Oxidation (PEO) for Aerospace Applications: A Review.

R. Barik, J. Wharton, R. Wood, K. Stokes, R. Jones, Corrosion, erosion and erosion–corrosion performance of plasma electrolytic oxidation (PEO) deposited Al2O3 coatings, Surface and coatings technology 199(2-3) (2005) 158-167.

L. Pezzato, M. Rigon, A. Martucci, K. Brunelli, M. Dabalà, Plasma Electrolytic Oxidation (PEO) as pre-treatment for sol-gel coating on aluminum and magnesium alloys, Surface and Coatings Technology 366 (2019) 114-123.

V. Dehnavi, B.L. Luan, D.W. Shoesmith, X.Y. Liu, S. Rohani, Effect of duty cycle and applied current frequency on plasma electrolytic oxidation (PEO) coating growth behavior, Surface and Coatings Technology 226 (2013) 100-107.

S.S. Kamble, A. Gunasekaran, S.A. Gawankar, Sustainable Industry 4.0 framework: A systematic literature review identifying the current trends and future perspectives, Process Safety and Environmental Protection 117 (2018) 408-425.

J. Parameswaranpillai, S.K. Sidhardhan, P. Harikrishnan, J. Pionteck, S. Siengchin, A.B. Unni, A. Magueresse, Y. Grohens, N. Hameed, S. Jose, Morphology, thermo-mechanical properties and surface hydrophobicity of nanostructured epoxy thermosets modified with PEO-PPO-PEO triblock copolymer, Polymer Testing 59 (2017) 168-176.

J. Curran, T. Clyne, Thermo-physical properties of plasma electrolytic oxide coatings on aluminium, Surface and Coatings Technology 199(2-3) (2005) 168-176.

V.T. Targhi, H. Omidvar, S.M.M. Hadavi, F. Sharifianjazi, Microstructure and hot corrosion behavior of hot dip siliconized coating on Ni-base superalloy IN738LC, Materials Research Express 7(5) (2020) 056527

A. Shirani, T. Joy, A. Rogov, M. Lin, A. Yerokhin, J.-E. Mogonye, A. Korenyi-Both, S.M. Aouadi, A.A. Voevodin, D. Berman, PEO-Chameleon as a potential protective coating on cast aluminum alloys for high-temperature applications, Surface and Coatings Technology (2020) 126016.

J. Guest, S. Papavinasam, N.S. Berke, S. Brossia, Corrosion Monitoringand Measurement.

Y. Rao, Q. Wang, D. Oka, C.S. Ramachandran, On the PEO treatment of cold sprayed 7075 aluminum alloy and its effects on mechanical, corrosion and dry sliding wear performances thereof, Surface and Coatings Technology 383 (2020) 125271.

T. Arunnellaiappan, S. Arun, S. Hariprasad, S. Gowtham, B. Ravisankar, N. Rameshbabu, Fabrication of corrosion resistant hydrophobic ceramic nanocomposite coatings on PEO treated AA7075, Ceramics International 44(1) (2018) 874-884.

E. Parfenov, A. Yerokhin, A. Matthews, Impedance spectroscopy characterisation of PEO process and coatings on aluminium, Thin solid films 516(2-4) (2007) 428-432.

A. Bahramian, K. Raeissi, A. Hakimizad, Characterizing of DC-Plasma Electrolytic Oxidation (PEO) Coatings on 7075 Aluminum Alloy.

V.T. Targhi, H. Omidvar, F. Sharifianjazi, A. Pakseresht, Hot Corrosion Behavior of Aluminized and Si-modified Aluminized Coated IN-738LC Produced by a Novel Hot-dip Process, Surfaces and Interfaces (2020) 100599.

E. Akbari, F. Di Franco, P. Ceraolo, K. Raeissi, M. Santamaria, A. Hakimizad, Electrochemically-induced TiO2 incorporation for enhancing corrosion and tribocorrosion resistance of PEO coating on 7075 Al alloy, Corrosion Science 143 (2018) 314-328.

H.P. Hack, J.R. Scully, Defect area determination of organic coated steels in seawater using the breakpoint frequency method, Journal of the Electrochemical Society 138(1) (1991) 33.

V. Egorkin, S. Gnedenkov, S. Sinebryukhov, I. Vyaliy, A. Gnedenkov, R. Chizhikov, Increasing thickness and protective properties of PEO-coatings on aluminum alloy, Surface and coatings Technology 334 (2018) 29-42.

I.S. Roncevic, Z. Grubac, M. Metikos-Hukovic, Electrodeposition of hydroxyapatite coating on AZ91D alloy for biodegradable implant application, Int. J. Electrochem. Sci 9 (2014) 5907-5923.

A. Hakimizad, K. Raeissi, M.A. Golozar, X. Lu, C. Blawert, M.L. Zheludkevich, The effect of pulse waveforms on surface morphology, composition and corrosion behavior of Al2O3 and Al2O3/TiO2 nano-composite PEO coatings on 7075 aluminum alloy, Surface and Coatings Technology 324 (2017) 208-221.

G. Paglia, C. Buckley, A. Rohl, B. Hunter, R. Hart, J. Hanna, L. Byrne, Tetragonal structure model for boehmite-derived y-alumina, Physical Review B 68(14) (2003) 144110.

Article DOR: 20.1001.1.26765837.2020.2.4.4.6

Published

How to Cite

Issue

Section

License

Copyright (c) 2020 JCC Research Group

This work is licensed under a Creative Commons Attribution 4.0 International License.