Investigation of aluminum oxide coatings created by electrolytic plasma method in different potential regimes

DOI:

https://doi.org/10.29252/jcc.2.3.2Keywords:

Electrolyte plasma method, Aluminum oxide coatings, potential applied regimeAbstract

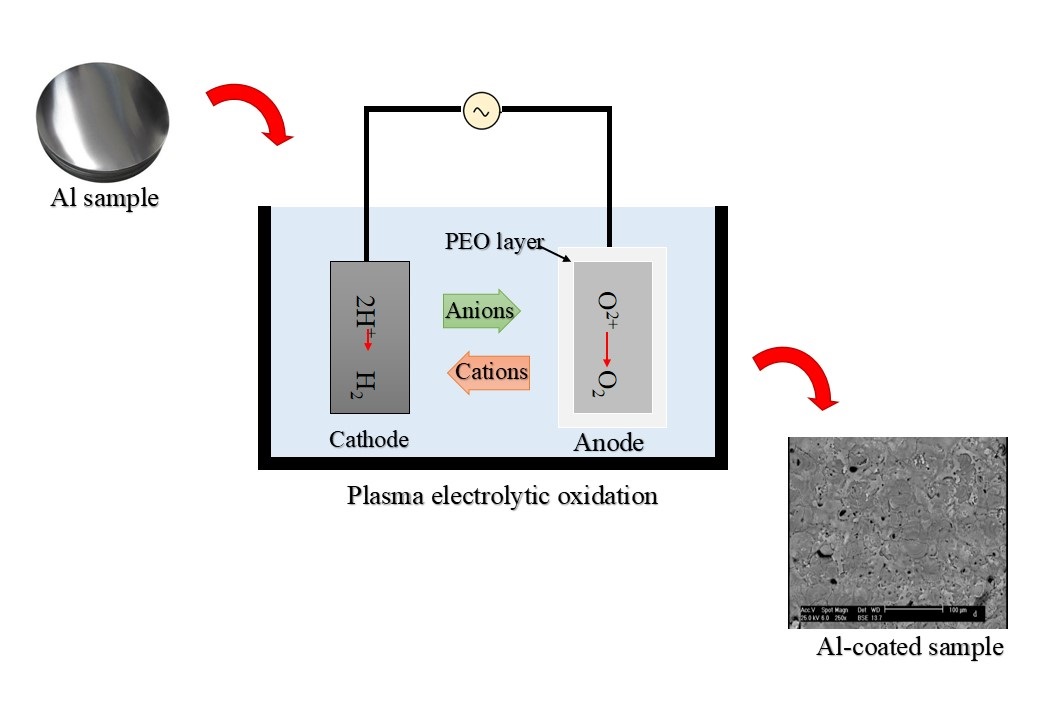

One of the most important coating methods on aluminum surfaces is the electrolytic plasma method. The main objective of the present study is to investigate the potential of aluminum oxide coatings created by electrolytic plasma method. Aluminum series 2 and the electrolyte of sodium silicate, sodium tetraphosphate, sodium aluminate, and potassium hydroxide were used. The results showed that the appropriate voltage to achieve uniform coating with ideal thickness and morphology is 500 V. Adding sodium silicate to the electrolyte solution will create porosity and non-adhesion to the substrate. On the other hand, the use of tetra sodium pyrophosphate increases the adhesion of the coating by penetrating phosphorus into the metal/coating interface. The optimum solution for plasma electrolytic oxidation coatings composed of 10, 3, and 3 g/l of tetra sodium pyrophosphate, sodium aluminate, and KOH, respectively. DC pulsed coating was shown to control the coating process and coating uniformity. In addition, the appropriate frequency to apply coating was DC pulse potential at 1000 Hz frequency under the 30% duty cycle.

References

V.A. Andrei, C. Radulescu, V. Malinovschi, A. Marin, E. Coaca, M. Mihalache, C.N. Mihailescu, I.D. Dulama, S. Teodorescu, I.A. Bucurica, Aluminum Oxide Ceramic Coatings on 316l Austenitic Steel Obtained by Plasma Electrolysis Oxidation Using a Pulsed Unipolar Power Supply, Coatings 10(4) (2020) 318.

T. Iman, G. Ehsan, Production methods of CNT-reinforced Al matrix composites: a review, Journal of Composites and Compounds 2(2) (2020).

Z. Kaiqiang, J. Ho Won, L. Quyet Van, Production methods of ceramic-reinforced Al-Li matrix composites: A review, Journal of Composites and Compounds 2(3) (2020).

E.H. Jazi, R. Esalmi-Farsani, G. Borhani, F.S. Jazi, Synthesis and Characterization of In Situ Al-Al13Fe4-Al2O3-TiB2 Nanocomposite Powder by Mechanical Alloying and Subsequent Heat Treatment, Synthesis and Reactivity in Inorganic, Metal-Organic, and Nano-Metal Chemistry 44(2) (2014) 177-184.

K. Zhang, H.W. Jang, Q. Van Le, Production methods of ceramic-reinforced Al-Li matrix composites: A review, Journal of Composites and Compounds 2(3) (2020) 77-84.

M. Fattahi, K. Vaferi, M. Vajdi, F. Sadegh Moghanlou, A. Sabahi Namini, M. Shahedi Asl, Aluminum nitride as an alternative ceramic for fabrication of microchannel heat exchangers: A numerical study, Ceramics International 46(8, Part B) (2020) 11647-11657.

B. Nayebi, A. Bahmani, M.S. Asl, A. Rasooli, M.G. Kakroudi, M. Shokouhimehr, Characteristics of dynamically formed oxide films in aluminum–calcium foamable alloys, Journal of Alloys and Compounds 655 (2016) 433-441.

A. Chlanda, P. Oberbek, M. Heljak, E. Kijenska-Gawronska, T. Bolek, M. Gloc, L. John, M. Janeta, M.J. Wozniak, Fabrication, multi-scale characterization and in-vitro evaluation of porous hybrid bioactive glass polymer-coated scaffolds for bone tissue engineering, Materials Science and Engineering: C 94 (2019) 516-523.

M. Shahedi Asl, B. Nayebi, M. Shokouhimehr, TEM characterization of spark plasma sintered ZrB2–SiC–graphene nanocomposite, Ceramics International 44(13) (2018) 15269-15273.

S.A. Delbari, B. Nayebi, E. Ghasali, M. Shokouhimehr, M. Shahedi Asl, Spark plasma sintering of TiN ceramics codoped with SiC and CNT, Ceramics International 45(3) (2019) 3207-3216.

V.T. Targhi, H. Omidvar, S.M.M. Hadavi, F. Sharifianjazi, Microstructure and hot corrosion behavior of hot dip siliconized coating on Ni-base superalloy IN738LC, Materials Research Express 7(5) (2020) 056527

V. Egorkin, S. Gnedenkov, S. Sinebryukhov, I. Vyaliy, A. Gnedenkov, R. Chizhikov, Increasing thickness and protective properties of PEO-coatings on aluminum alloy, Surface and coatings Technology 334 (2018) 29-42.

B. Kasalica, M. Petkovic-Benazzouz, M. Sarvan, I. Belca, B. Maksimovic, B. Misailovic, Z. Popovic, Mechanisms of plasma electrolytic oxidation of aluminum at the multi-hour timescales, Surface and Coatings Technology 390 (2020) 125681.

T. Kikuchi, T. Taniguchi, R.O. Suzuki, S. Natsui, Fabrication of a plasma electrolytic oxidation/anodic aluminum oxide multi-layer film via one-step anodizing aluminum in ammonium carbonate, Thin Solid Films 697 (2020) 137799.

S. Wang, X. Liu, X. Yin, N. Du, Influence of electrolyte components on the microstructure and growth mechanism of plasma electrolytic oxidation coatings on 1060 aluminum alloy, Surface and Coatings Technology 381 (2020) 125214.

N. Angulakshmi, R.B. Dhanalakshmi, M. Kathiresan, Y. Zhou, A.M. Stephan, The suppression of lithium dendrites by a triazine-based porous organic polymer-laden PEO-based electrolyte and its application for all-solid-state lithium batteries, Materials Chemistry Frontiers 4(3) (2020) 933-940.

R. Hussein, D. Northwood, X. Nie, The effect of processing parameters and substrate composition on the corrosion resistance of plasma electrolytic oxidation (PEO) coated magnesium alloys, Surface and Coatings Technology 237 (2013) 357-368.

B. Ghorbanian, S.M.M. Khoie, Formation of vanadium carbide with the plasma electrolytic saturation method (PES) and comparison with Thermo Reactive diffusion method (TRD), Acta Metallurgica Slovaca 22(2) (2016) 111-119.

A. Yerokhin, X. Nie, A. Leyland, A. Matthews, S. Dowey, Plasma electrolysis for surface engineering, Surface and coatings technology 122(2-3) (1999) 73-93.

B. Ghorbanian, S.M.M. Khoie, M. Rasouli, R.J. Doodran, Investigation of the electrolyte effects on formation of vanadium carbide via plasma electrolytic saturation method (pes), Surface Review and Letters 23(04) (2016) 1650021.

Y. Gao, B. Ghorbanian, H.N. Gargari, W. Gao, Catalytic activity of char produced from brown coal for steam-gasification of bitumen oil, Petroleum Science and Technology 36(1) (2018) 75-78.

Y. Gao, B. Ghorbanian, H.N. Gargari, W. Gao, Steam gasification of bitumen oil in presence of Ni/dolomite catalysts, Petroleum Science and Technology 35(21) (2017) 2074-2079.

F. Momeni, B. Ghorbanian, S.M.M. Khoie, S.M.M. Nazari, M. Rasouli, Study of Current and Voltage Diagram In The Formed Vanadium Carbide Coatings Via Plasma Electrolytic Saturation Method, JOURNAL OF MATERIALS 7(11) (2016) 4073-4078.

V. Dehnavi, B.L. Luan, D.W. Shoesmith, X.Y. Liu, S. Rohani, Effect of duty cycle and applied current frequency on plasma electrolytic oxidation (PEO) coating growth behavior, Surface and Coatings Technology 226 (2013) 100-107.

V.T. Targhi, H. Omidvar, F. Sharifianjazi, A. Pakseresht, Hot Corrosion Behavior of Aluminized and Si-modified Aluminized Coated IN-738LC Produced by a Novel Hot-dip Process, Surfaces and Interfaces (2020) 100599.

S. Rahimi, F. SharifianJazi, A. Esmaeilkhanian, M. Moradi, A.H. Safi Samghabadi, Effect of SiO2 content on Y-TZP/Al2O3 ceramic-nanocomposite properties as potential dental applications, Ceramics International 46(8, Part A) (2020) 10910-10916.

M. Alizadeh, M.H. Paydar, F. Sharifian Jazi, Structural evaluation and mechanical properties of nanostructured Al/B4C composite fabricated by ARB process, Composites Part B: Engineering 44(1) (2013) 339-343.

J. Curran, T. Clyne, Thermo-physical properties of plasma electrolytic oxide coatings on aluminium, Surface and Coatings Technology 199(2-3) (2005) 168-176.

Y.-J. Oh, J.-I. Mun, J.-H. Kim, Effects of alloying elements on microstructure and protective properties of Al2O3 coatings formed on aluminum alloy substrates by plasma electrolysis, Surface and Coatings Technology 204(1-2) (2009) 141-148.

Article DOR: 20.1001.1.26765837.2020.2.4.2.4

Published

How to Cite

Issue

Section

License

Copyright (c) 2020 JCC Research Group

This work is licensed under a Creative Commons Attribution 4.0 International License.