Exploring 3-D printing: additive manufacturing for metallic components, processes, structures, and properties

DOI:

https://doi.org/10.61882/jcc.6.2.2Abstract

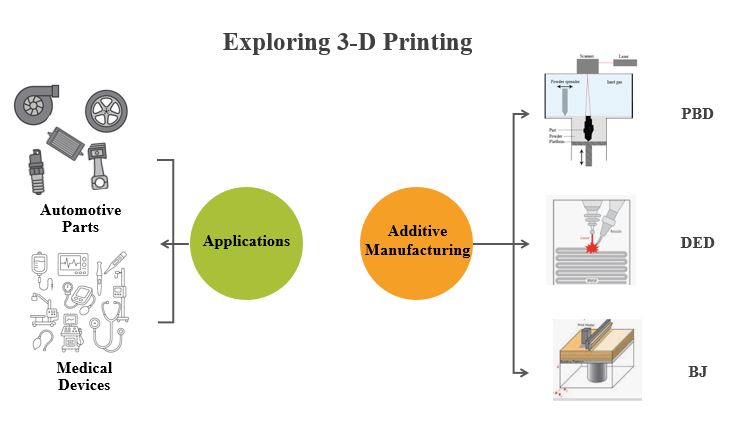

This study offers a comprehensive analysis of metal additive manufacturing (AM), a production technique that uses digital 3D models to directly construct intricate metallic components layer by layer. It discusses the key procedures in metal AM, such as directed energy deposition (DED), binder jetting (BJ), and powder bed fusion (PBF), emphasizing how they can create parts with complex geometries that are impossible to achieve with conventional manufacturing techniques. In addition to addressing issues like anisotropy and joint flaws related to the process, the focus is on metal additive manufacturing's exceptional ability to produce components with complex geometries and specific microstructures that traditional manufacturing cannot provide. The paper also explores the significance of post-processing approaches for performance enhancement and how process parameters influence the mechanical and structural properties of the produced components. Applications in the industrial, automotive, and medical fields highlight the technology's versatility and growing market potential. By integrating digital design with functional metal components, this synthesis aids in the design, optimization, and selection of suitable metal AM methods for advanced metallic component manufacture.

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 .

This work is licensed under a Creative Commons Attribution 4.0 International License.